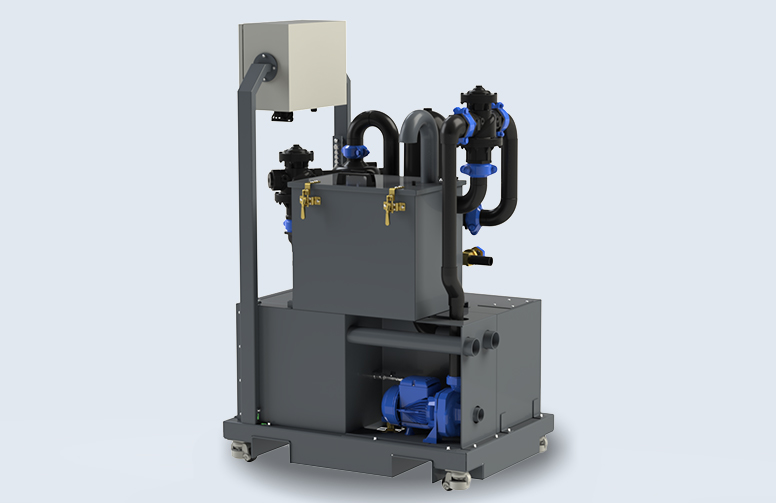

The ECO Flow System is a compact, semi-automatic filtration system designed to ensure continuous coolant purity in machining processes. Powered by Amiad’s proven Spin Klin™ disc technology and intelligent self-cleaning control, it delivers consistent performance, reduced maintenance, and lower operating costs.

This compact and flexible system provides a solution for various needs, including sidestream and/or fullstream filtration, improves the coolant quality in the existing systems, reduces maintenance costs and increases production efficiency.

It is engineered to handle a wide variety of cutting fluids—including synthetic, semi-synthetic, water-based emulsions, and neat oils—making it ideal for both internal tool cooling and external coolant circuit applications.

By keeping coolants clean, the ECO Flow System protects valuable machinery, extends tool life, and improves the consistency and quality of finished parts. Its energy-efficient design and modular build ensure reliable operation with minimal footprint and maximum durability.

Easy to install, operate, and maintain, the ECO Flow System is built with high-quality components to support long-term industrial use.

The following options can be added to the ECO Flow System

- Chiller

- Oil skimmer

- High-pressure pump

- Different clean tank sizes

- Longer lifetime for machines and tools

- Longer lifetime for pumps and spindles

- Reduced maintenance costs

- Improved production efficiency

- Increased productivity

- Reduced machining downtime

- Longer coolants lifetime

- Less disposals

- Reduced CO₂ footprint