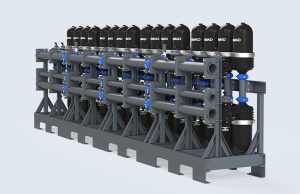

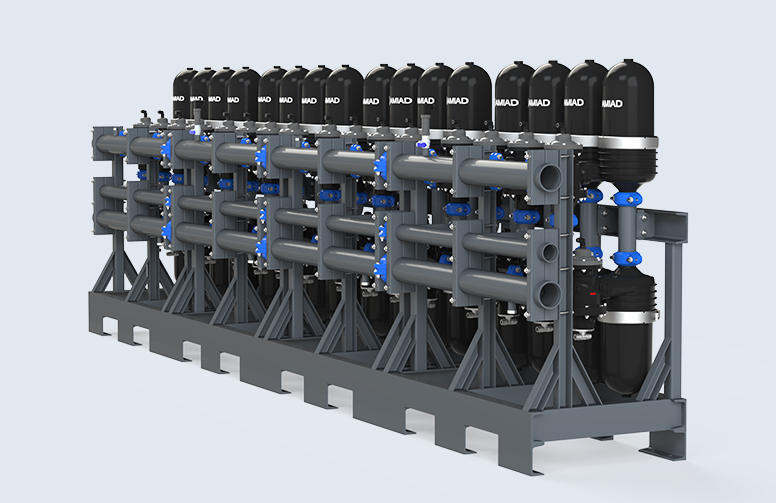

The ECO Flow Modular system is designed to be fully scalable, adapting to your specific requirements. It employs Amiad’s advanced Spin Klin™ disc technology and intelligent control systems to deliver automatic filtration and backflush. This ensures the purity of machining coolants, enhancing performance, reducing costs, and improving energy efficiency.

ECO Flow Modular allows for future expansion, enabling the addition of machines or modifications to the manufacturing process, quickly and easily, with minimal downtime.

The system is compatible with various cutting fluids, including synthetic, semi-synthetic, water-based emulsions, and cutting oils, and is suitable for both fullstream and sidestream applications.

Constructed with premium materials for durability, the ECO Flow Modular is easy to install, operate, and maintain. Its automated self-cleaning feature guarantees uninterrupted operation with minimal downtime.

This system is the smart choice for manufacturers aiming to optimize coolant management while boosting efficiency, reliability, and environmental sustainability.

Units with 2, 3, and 4 pods as well as combinations thereof are available for flow rates of up to 1,500 lpm.

- Longer lifetime for machines and tools

- Longer lifetime for pumps and spindles

- Reduced maintenance costs

- Improved production efficiency

- Increased productivity

- Reduced machining downtime

- Longer coolants lifetime

- Less disposals

- Reduced CO₂ footprint