![]() Country

Country

Germany

![]() Application

Application

Cast Iron Processing

![]() Liquid type

Liquid type

Emulsion

![]() Filtration solution

Filtration solution

ECO Flow 2.0

Background

A company with 15,000 employees worldwide, and many facilities around the globe, was looking to improve the CNC processes in their gear motor plant.

The processes at this plant include milling, turning and grinding.

The plant turns parts of the gear housing, constructed out of cast iron Type GG25, on a Hessapp DVT 400 Vertical Turning Centre.

Challenge

The small highly adhesive and abrasive particles in the emulsion damaged several CNC components, such as the expensive rotary feedthrough of the spindle.

The existing conventional paper roll filter at the site was not efficient with these types of particles.

Replacing the damaged components resulted in added costs exceeding €10K per year.

Solution

Amiad went to the site to review the process and presented various possibilities to the customer, including an offer of a free trial phase. This offer was accepted, and Amiad delivered a demo unit.

The ECO Flow 2.0 automatic depth filtration unit was delivered and installed on the sidestream, to circulate the fluid in the clean tank for finer filtration degrees.

• Flow rate: 40 l/min

• Filtration degree: 40 μm

• Material: Cast iron GG25

Results

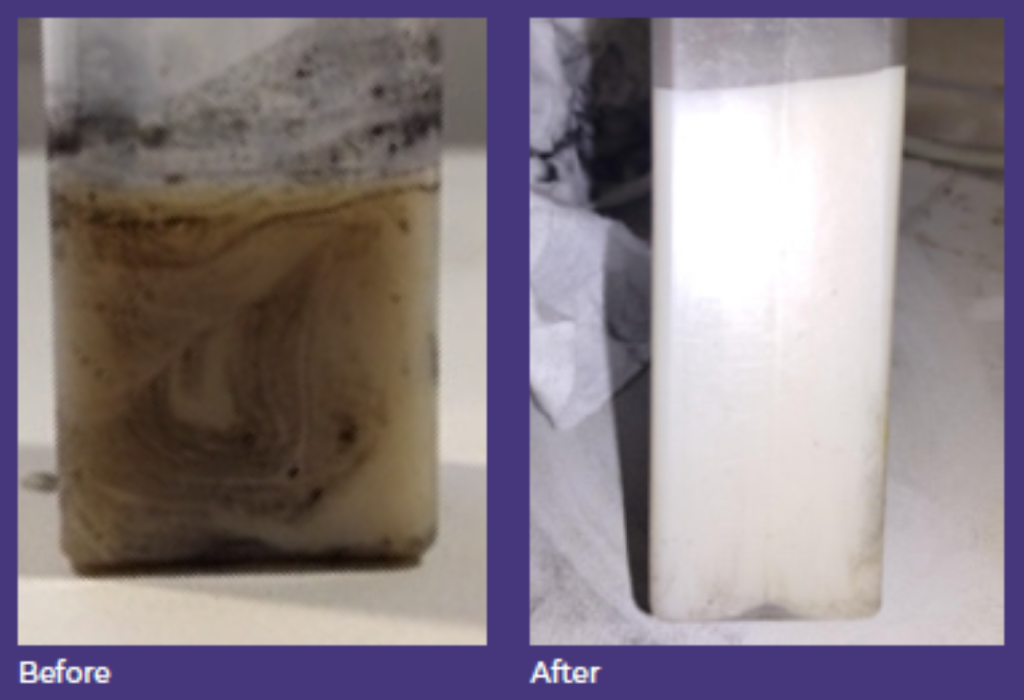

After only a few days, the dark grey of the particle-filled emulsion turned into a clean white, as can be seen in the before and after pictures.

The system’s backwashing was flawless at all times, and the continuous operation can be guaranteed in the future.